Since 2016, PTC have been manufacturing components for the Domestic Aerospace sector and have recently embarked on the AS9100 and NADCAP qualification process to serve our European and North American customers.

Our state of the art Aerospace facility comprises of in house capability from pattern manufacture through to final machining of components in Titanium and High Nickel Super Alloys. Using our unique Printcast technology, PTC can produce patterns in a very short timeframe so can offer regular production runs with extremely high repeatability and integrity.

With the increased world demand for Liquified Natural Gas (LNG) or Liquified Petroleum Gas (LPG), PTC have been at the forefront of casting development for this sector. Supplying Cryogenic valve components to leading LNG Valve manufacturers, PTC has a reputation for manufacturing the high consistent quality needed for this critical application.

The traditional Oil & Gas market sector has been the backbone of PTC’s Casting business since the 1960’s and has helped the business develop into the large scale reputable manufacture of High Quality castings that it is today. With experience producing near net shape valve castings, and complex geometry ancillary components, PTC has the technical excellence to work with you for both volume production, but also complex, low volume specialist parts in unique alloys or extremely corrosive working environments.

The PowderForge technology can complement the traditional casting manufacturing offering by offering bi-metal solutions for extreme working environments, where traditionally a corrosion or wear resistant overlay was applied. This HIPped Metal Powder solution is available in house and can be supplied as a complete offering with the casting process.

In the diverse marine sector, PTC have been supplying high integrity Cast products for 60 years to customers across the globe. The range of valve and hull components have been manufactured using the Replicast process, which was the original Casting technology installed at PTC in the 1960’s. Since then, our processes and technologies have supported the development of products and materials for this industry, delivering high integrity components in a range of materials including Nickel Aluminium Bronze (NAB), Stainless Steel, Duplex Stainless Steel and Titanium.

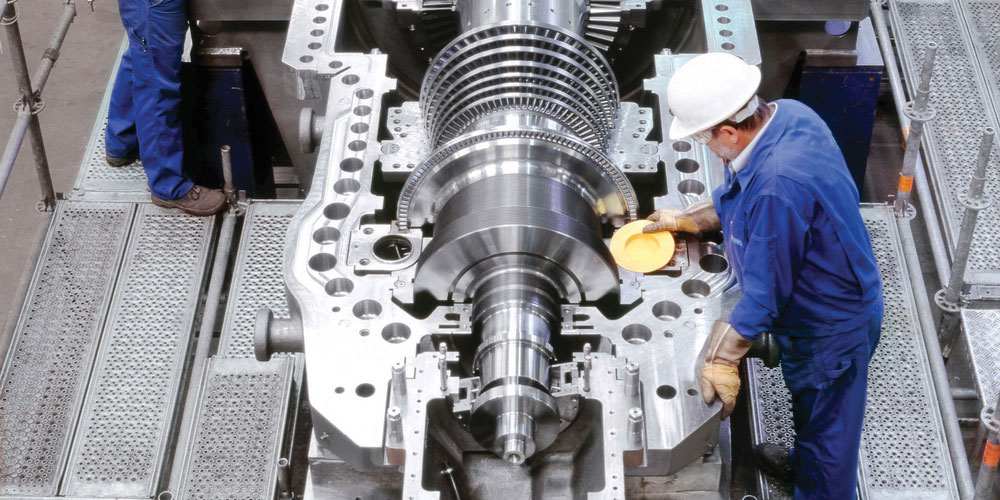

As a result of the energy challenges faced across the globe, and the development of renewable and sustainable sources of power generation, PTC have been chosen by leading domestic and international manufacturers of this equipment to supply critical components in a range of alloys, including Carbon Steel, Stainless Steel and Duplex Stainless Steels. To support this changing market, PTC have developed a range of technologies that will complement the products traditionally manufactured from a sand casting or investment casting process.

There is a continuous demand globally for environmentally sustainable packaging solutions, driving demand for effective Valve products within this sector. PTC have been supplying Valves in this market for over 40 years and have supported our customers with product and material enhancements to help them maintain their competitive advantages in their domain. Our long standing partnerships have demonstrated our capability as a leading manufacturer of near net shape cast parts in a range of carbon steel, stainless steel, duplex and titanium materials.

PTC has many years of experience in manufacturing of castings for a variety of engineering like Railways , Pulp & Paper , Petro chemical , mineral , mining & pulverising etc . PTC Manufactures casitings in a variety of alloys including Steel , Stainless Steel , Nickel Aluminium Bronze ( NAB ) , Inconel , Hastealloy & Titanium alloys. Oil & Gas related castings manufactured by us range from a few kgs to 5,000 kgs single piece.